Saving the water when repairing the dump tank

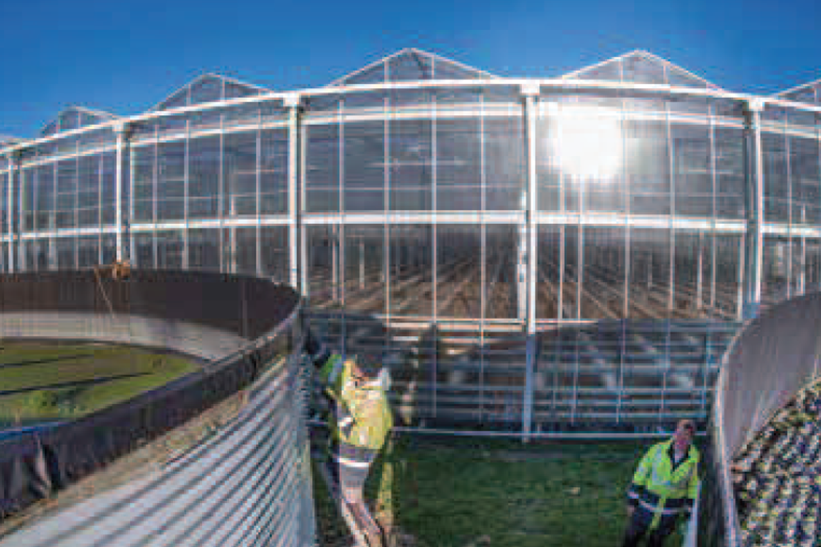

On a fresh sunny morning driving along the heat storage tank it shows a small feather of vapour Leakage! Repairing the tank seems like a simple task, but where to go to with 5,000 m3 of water and how do I get the tank refilled?

As a dump tank owner, you will recognize situations of spill water. The causes: rainwater that gathered underneath the floor, a roof that does no longer closes properly or a mistake made during the building process. The result is the same, water pours out of the tank which in the end could lead to dangerous situations.

Tank builders can sometimes repair the tank even if it remains filled with water. They lower the temperature to below 35 degrees and use a diver with that knows how to weld under water. But in most situations the tank must be emptied and cleaned before repair is possible. Getting the water out takes time (don’t forget the air inlet!) and where to leave it? Is costs a fortune to dump it because of environmental regulations. And the owners like to have it back in the tank because it’s conditioned. Filling the tank with new water is expensive, it needs treatment and it takes a lot of time.

Recently in some situations water was collected in bags used by farmers to temporary store their manure. Another grower filled a lagoon with tank water. If the space is there it’s even possible to dig a hole and cover it with liner. If a second liner is used on top than the absorption of oxygen is limited and only little treatment refilling the tank will be necessary. Using this strategy getting the water back in with big pumps makes the total stand still down time shorter and the costs of reconditioning the water will be limited.